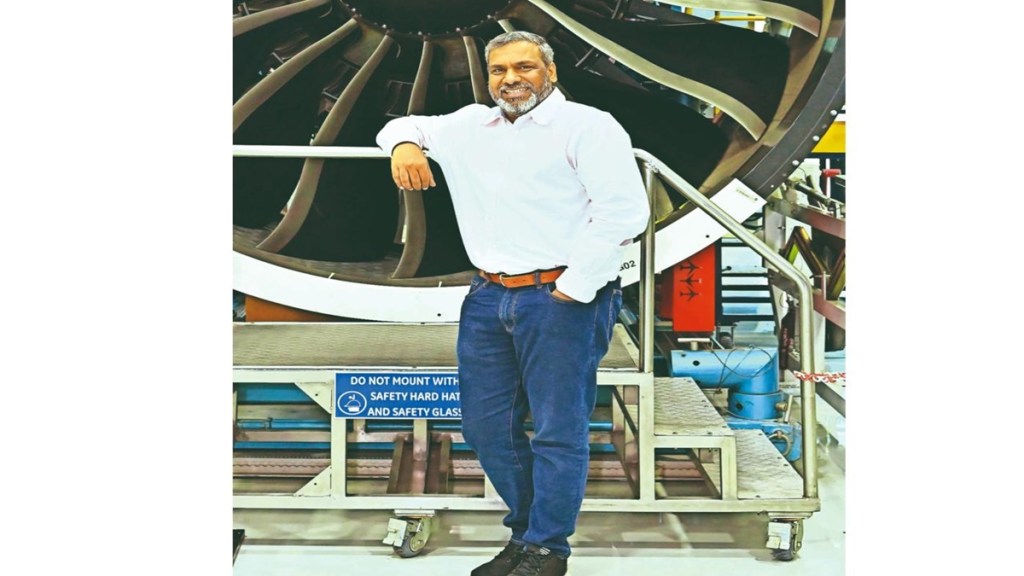

GE Aerospace has started to deploy a new, AI-enabled blade inspection tool to improve accuracy and consistency for key components of narrow-body aircraft engines, helping return engines to be serviced faster. Over the past decade, the Cincinnati, Ohio-based group has established one of the largest portfolios of AI-related patents in the aviation industry. It employs more than 100 specialists focused on AI and data science. In this interview, Dinakar Deshmukh, vice-president, Data Science & Analytics, GE Aerospace, speaks to Sudhir Chowdhary on how the company is integrating AI across its operations. Excerpts:

How is GE Aerospace using AI in engine health management?

We’ve been deploying cutting-edge technologies to monitor every flying commercial engine 24/7. We use machine learning (ML) models to build what we call digital twins — virtual models that simulate each flight. Our strategy combines deep domain expertise in jet engine design and physics with modern technologies like ML and AI. This fusion enables us to create highly effective predictive models. We’ve been using this approach for over a decade, and it has delivered significant benefits: we’ve reduced false positives by over 50% and improved detection rates by 45%.

AI as a technology isn’t new —but what’s changing now is the emergence of GenAI. At GE Aerospace, it’s influencing both how we design products and how employees operate on a daily basis. GenAI will have a major impact not just on engineering design, but on workflows across the organisation.

Take for instance, blade inspections. How can AI be utilised?

We’re expanding our use of AI across the broader ecosystem of jet engine maintenance, including inspection technologies. In simple terms, every jet engine is inspected using a small probe that takes images of internal components. We’ve introduced AI-based, computer vision solutions that help operators position these probes more accurately and reduce inspection time — by about 50%. We’ve deployed AI-enabled blade inspection tool both in the field and across our MRO facilities. What’s powerful here is that it not only ensures consistency and faster inspections, but also captures rich image data. This data feeds into our digital twin models, enhancing our predictive maintenance capabilities.

Isn’t scaling AI across global operations arduous?

Running proof-of-concept projects on a small scale is relatively easy—but scaling them across a large enterprise requires a different mindset and structure. Our approach combines Digital and Lean principles. Digital enables rapid iteration and experimentation with new technologies, while Lean provides the structural discipline to ensure solutions are robust and impactful.

All our AI initiatives are grounded in these principles: building high-impact, reliable solutions that scale. We refer to this integrated model as Flight Deck – GE Aerospace’s proprietary operating system—which brings the structure and rigour to deliver real customer value.

How is AI contributing to improved safety standards and operational efficiency?

There are two main elements here. First, any AI solution we develop must be robust, safe, and reliable. To that end, GE Aerospace is a leading member of the National Institute of Standards and Technology (NIST) consortium, helping to shape industry-wide frameworks for safe and reliable AI deployment.

Second, AI enhances operational efficiency. A good example is our White Light Inspection system – an AI-powered technology where two robots, in collaboration with a human operator, inspect every detail of critical parts. The precision achieved through this method far exceeds human visual inspection. It lets us scan components down to micrometre levels, ensuring nothing is missed.

What role does the John F Welch Technology Centre (JFWTC) play on the innovation front?

This is close to my heart, as I began my career at JFWTC in Bengaluru before moving to Cincinnati. What makes the centre unique is its multidisciplinary setup: engineering, digital, and research teams work side by side to develop next-gen technologies. The centre played a key role in developing the GEnx, GE LEAP, and GE9X engines. Over the past 25 years, the centre has contributed to over 1,000 patents related to jet engine design.

Beyond that, JFWTC is instrumental in shaping the next generation of engines and in scaling AI solutions. For example, our predictive maintenance solutions powered by digital twins were developed here.

Some in the aviation industry feel that GenAI could someday design entire aircraft…

GenAI has opened up new ways of thinking about engineering and design. While fully designing an aircraft may still be a way off, we’re already using elements of GenAI to enhance how we design jet engines. More broadly, GenAI is transforming how employees work. For instance, we’ve deployed an enterprise-wide GenAI platform – developed with Microsoft—that functions like an internal ChatGPT for GE Aerospace. It gives employees quick access to answers based on our internal knowledge base. In just nine months, the platform has processed nearly 3 million queries.

We’re also applying GenAI to maintenance records in our MRO operations, enabling technicians to retrieve insights quickly without digging through complex documents.