In a change of approach, Elon Musk’s Tesla is now considering manufacturing in India and is no longer pressing with its earlier demand for first, lowering import duty on completely built units, which is at 100% for cars costing $40,000 and above.

The duty on cars costing below this is at 60%. Tesla’s demand in the past was to slash the duty to 40%.

Government sources told FE that the Tesla team, which has come to India and is having a series of meetings with key ministries as well as officials in the Prime Minister’s Office (PMO), comprises supply chain executives, who have drawn up a manufacturing plan for India.

Sources said that Tesla may still ask for some duty concessions but that would be for testing the market for some of its models, which may not have high domestic demand.

Opening exclusive showrooms under single brand retail, which requires 30% local sourcing, is also on the agenda.

Sources said that the change in Tesla’s approach — from asking for a reduction in import duty first and then probably looking at domestic manufacturing — came after seeing the success of Apple’s domestic manufacturing in the country. Government officials told Tesla that its demand for import concessions can be met albeit differently. Instead of importing CBUs at concessional duty, the government was ready to offer import duty concessions to the company on the components which are required for domestic manufacturing. Such a scheme currently works for the smartphone production-linked incentive scheme under the phased manufacturing programme (PMP).

At a recent FE event, road transport and highways minister, Nitin Gadkari said that Elon Musk and Tesla are welcome in India but if they want to manufacture in China and market in India, it is not possible. “We are open to concessions, subsidies if they manufacture here,” Gadkari had said.

“The electric vehicle PLI also offers such incentives and the same can be offered to Tesla if they look at domestic manufacturing,” officials said.

Sources said that offering concessional import duty for domestic manufacturing may not be compliant with World Trade Organisation’s norms, but the entire process of appealing in WTO and the appellate processes that follow take long years, by when Tesla’s indigenous supply chain would be in place.

“By that time the PMP would have run its course and Tesla would have developed indigenous supply chain for domestic manufacturing,” officials said. This approach successfully worked in the case of auto industry several years back when foreign manufacturers were setting up base in India and a PMP was put in place for them to meet local sourcing guidelines. By the time the case went against India in WTO, the indigenous supply chain was in place, officials added.

Officials said that if Tesla is given concessions in imports for domestic manufacturing, the domestic auto industry would not object. But in the case of lowering import duty for their finished cars would be objected by the industry as it would be against a level-playing field. Industry body, the Society of Indian Automobile Manufacturers (Siam) has in the past already raised its objection to any special concessions for Tesla at the cost of the domestic industry.

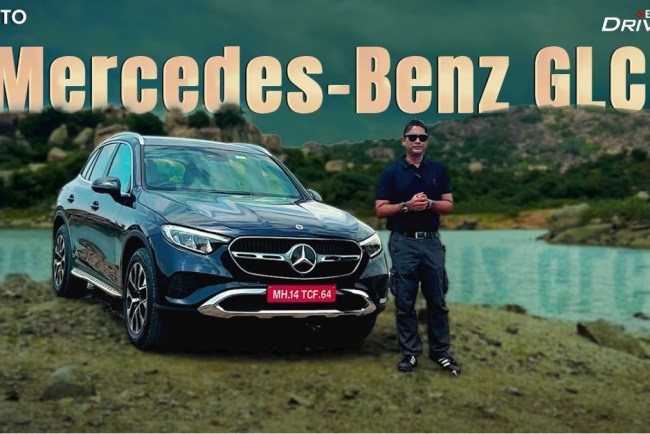

Currently, global auto manufacturers like Mercedes and Volkswagen assemble cars in India by bringing completely knocked down kits. They add some components through local sourcing.