On a searing hot day in Mohali, passing through the top floor of Semi-Conductor Laboratory’s (SCL) three-tier fabrication building is a refreshing experience as it houses the air circulation system. On the first floor are all the equipment and machines, while the ground floor has utilities such as ultrapure water pipelines and management system, gas pipes, as well as chemical delivery systems.

It takes 450 steps starting from getting a raw wafer, performing cleaning steps and complex processes for multiple chips on the wafer, till the wafer goes for packaging and assembly. The process involves patterning or lithography on the wafer, which means passing chip design onto the wafer for defining circuits after which they are cleaned and polished.

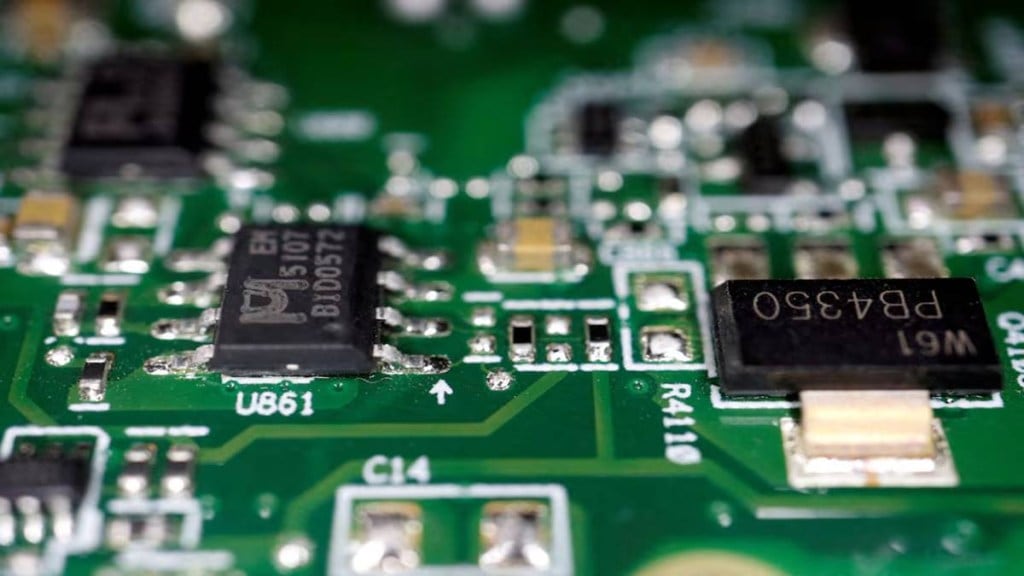

Next comes etching, which means removing the material and creating layers of chips. After this, the transistors are inter-connected and joined to the aluminium pad, which are then connected to outer world with thin wires.

“Of the 450 steps, 30% comprise the cleaning process,” says Manoj Wadhwa, group head at VLSI (very large scale integration) and MEMS (micro-electromechanical system) fabrication at SCL. Visiting the “Class 1 clean room” at SCL is in itself an experience. Clean room environment is critical for semiconductor fabs to reduce contamination during processing. The Class 1 clean room undergoes 540 air changes per hour for cleanliness.

In absence of wafer making facilities in the country, SCL imports 10,000 wafers a year at a price of $25-30 per wafer. The raw wafers come in vacuum sealed boxes, and are sent to class 1 clean room. From there they are loaded in SMIF (standardised mechanical interface) pods, and post that wafer processing is done in vacuum chambers. All machine loaders have Class 1 mini-environment, Wadhwa explains.

While passing through the equipment area, one can see machines like lithography system, plasma etcher, defect inspection stations, cleaning stations, photoresist coater, among other tools, which are used. On the other side, technicians load recipes to process wafers. A recipe refers to a set of specific instructions or parameters used to perform a particular manufacturing process.

These instructions are typically stored in the fab’s manufacturing execution system or process control system. Of the 700 wafer capacity, SCL is currently processing approximately 250 wafers a month.

The utility area on the ground floor is filled with the noise of heavy loaded, large piping infrastructure, which carries ultrapure water and different gasses. SCL uses 110 gallons of ultrapure water per minute, and 40% of the water is reclaimed by SCL for horticulture as well.

All gas lines are double-lined, with nitrogen in outer lines, as a safety measure. Since these are hazardous gasses, in case of any leakage, the system will flush it with nitrogen, which is considered a safe gas. Along with this, toxic gas monitoring systems are installed which shut down the gas source supply in case of any gas leak.

Over 30 types of gases are used at the facility, which are imported as well as sourced from companies such as Inox, Linde, among others.

Over the years, SCL has kept on advancing its technology to meet the needs of the strategic sectors. Since its current mandate is limited to serving only the strategic sectors and organisations, SCL’s revenue is very low — in the range of Rs 1-3 crore. Expenses such as salary and repair and maintenance largely get fulfilled by grants of around Rs 400 crore by the government.

In FY24, owing to increase in the order size, the company’s revenue rose 10 times to Rs 32 crore.

Sudhir Thakur, group head, project planning group at SCL, who also took the initiative of setting up a marketing team, says “we are getting orders and for FY25, we have set a target of Rs 40 crore revenue”.

Currently, SCL is spending close to Rs 127 crore annually on repair and maintenance of equipment, followed by salary expenses of Rs 117 crore annually.

A higher repair expense can also be attributed to refurbishing old equipment. The modernisation project will also look into replacing them.

“Suppose, out of 74 equipment, one equipment is down, the whole line will stop working.

We then need to order necessary parts, which delays our project delivery time,” Thakur said.

Putting all of these together is SCL’s 513 employees, of which 421 are from the technical side, including 100 working on the fab side. The remaining 92 are administrative staff.

Ganesh, who has been working for over 35 years in the technical team at SCL said, “whatever (semiconductor chips, sensors) is not being made in India, we are making it at SCL. That’s the motivation we have. Our employee strength is competent enough to take on any challenge”.

With bigger private firms now entering the chip space, retention of talent is going to be a big challenge for SCL. It plans to redeploy the staff who are superannuating. A new technology partner, coupled with the execution of the modernisation plan, hold the key to the future of SCL as the country rides the chip boom.

Wadhwa says he is confident of SCL’s growth story as the country is focusing on self-reliance. “If we look at imports in the strategic sectors, it’s huge. Even if 30-40% of imports are met domestically, our order book will get a big boost,” he said. The country will be hoping the same from its first semiconductor fabrication facility.