Schaeffler Group has been investing in new technologies to future-proof itself. In India, too the company has been working closely with traditional as well as new-age companies to support their future plans. Speaking to Financial Express Online, the India MD highlights that electrification does have certain limitations and this is why hydrogen as a fuel alternative could be a potential disruptor.

In a recent free-wheeling interaction with Financial Express Online, Harsha Kadam, MD & CEO, Schaeffler India, said that “the most important thing that is driving the automobile industry today globally is obviously decarbonisation. With the Paris Accord there’s a very clear decision taken that we have to get the global temperature down by 1.5 degrees. And the transportation segment apart from of course the industrial segment becomes two important areas that every organisation, every country needs to address.”

He acknowledged that while electrification presents an alternative solution in certain vehicle segments, there are challenges associated such as the availability and extraction of lithium, energy production, and storage among others. This is where hydrogen as a fuel would be a potential disruptor.

“Hydrogen is touted to be the cleanest because when you use hydrogen to convert it into electricity, the exhaust gas is nothing but water vapour. This is clearly scientifically proven now. Now the question is to get the technology in place economically. That is where commercial viability is coming up as a challenge,” added Kadam.

He highlighted that Schaeffler has kept a target of achieving carbon neutrality by 2040, compared to Germany’s target of 2045, “We have a three-pronged approach by way of green products, by way of green production and green materials. By addressing all these three areas we are addressing our entire value chain.”

Hydrogen, fuel-cell and electrolysers

Hydrogen as a chemical element is one of the most abundant resources available in nature, and its potential use as an energy source is being termed as the most promising. In the automotive space, hydrogen as a fuel is already being explored by the industry globally as well as in India.

A number of pilot projects have been undertaken across vehicle segments to understand the feasibility of the technology for the country.

Schaeffler too is working on hydrogen technology and is “closely working with the industry in India”.

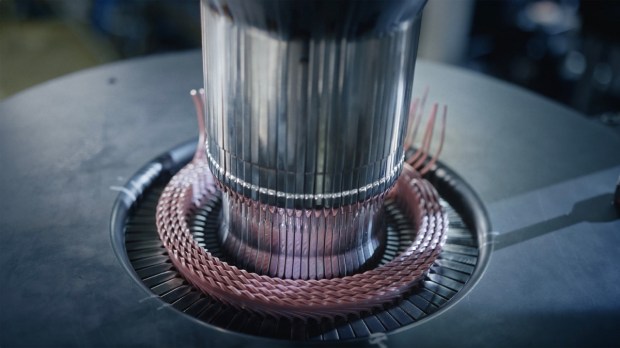

“I see fantastic opportunities for Schaeffler. Why hydrogen as a fuel? It is the cleanest fuel and the fuel of the future. It’s going to make fossil fuel zero in the next few years. That said producing green hydrogen is one technology and that’s where Schaeffler has products. It’s called electrolyser which is required to convert the other colours of hydrogen gasses into green hydrogen. This is required if you have to use hydrogen in fuel cell. Because the input for a fuel cell – green hydrogen – has to be clean, and pure, and it should be from a source of green route of manufacturing. It cannot be through again burning fossil fuel to produce green hydrogen,” he explained.

Kadam acknowledged that while there is interest in India around electrolysers it is still some time away before Schaeffler starts manufacturing it in India. “We have been discussing it with quite a few customers because they are showing interest.”

According to him, “We want to see where we want to position ourselves. In our portfolio, we have Energised Motion under that hydrogen fuel cell and electrolyser. For Fuel cell, we are at a much-matured stage and have the know-how to design and to also manufacture. We have a series production lines in Germany and some in Japan. We are primarily focused on passenger cars as they are the first early adopters of this. Of course, rightfully buses are also there. The public transportation system is going to go the fuel cell way. But again, not many demonstrators are there.”

Responding to India’s potential, Kadam mentioned that at present, the country contributes around 24-26 percent of the revenue for Schaeffler in the Asia-Pacific region (barring China) in a close race with South Korea for the number one spot. “The sky is the limit for us. We will continue to invest and build on our successes.”

Parts supplier to integrated systems supplier

In contrast- the megatrend of electrification presents both an opportunity and a challenge globally for the automotive ecosystem. This is due to the fact that, unlike the traditional IC-engine vehicle, many mechanical parts become redundant in an EV. On the other hand, the EV itself requires much more technologically advanced parts that rely more on electronics, software, and systems.

This means, that OEMs are preferring suppliers who can provide a complete integrated system versus sourcing multiple components and assembling them together.

Schaeffler too has developed capabilities to “design, develop, and manufacture electric motors, plus the transmission gearboxes and their associated components around it in-house. We are working with partners on the control units for electronics. Because we have never been in the electronics game. But that’s something we now have dependable partners and we work with them globally. In a nutshell, we are in a position to offer the entire powertrain, whether it’s a car, a bus or a light commercial vehicle,” pointed out Kadam.

At present, Schaeffler has 4 plants in India and has been investing close to Rs 300-350 crore every year for the last few years. “Our investment ratio used to be around 3% of the total sales till a few years back. Last year we ended that at 6% of our sales. We have doubled our investments and expect this to only grow further. We have also gone public in saying that we will continue to invest close to another Rs 1,500 crore in the next three years,” Kadam shared.

For CY2022, Schaeffler India reported revenue of Rs 6,945 crore, up 23.3 percent, and net profit of Rs 829 crore, up 40 percent.

Interestingly, the company has also started benefiting from its diversification strategy and won orders from a leading OEM to supply e-axles, which Schaeffler will “start producing locally in the coming few years.”