The Mercedes-Benz EQS 580 4Matic has been recently launched in India at Rs 1.55 crore, ex-showroom. Arup Das, Editor – Express Drives, has a quick chat with Vyankatesh Kulkarni, Executive Director and Head of Operations, Mercedes-Benz India. They talk about what to expect from the locally assembled Mercedes-Benz EQS 580 and how the company plans to support the EV ecosystem.

Mercedes-Benz has made history in India by becoming the first company to locally assemble a luxury vehicle, the EQS 580. It is also the first time Mercedes-Benz is rolling out the EQS outside Germany. How did the company manage to make this a reality?

The first step to go towards the electrification journey is this car, the EQS 580 and that is to first locally produce a luxury electric vehicle. After taking the first step, the localization process is the following steps in that journey. Today, when I speak about the whole vehicle, we don’t have localization in terms of the part sourcing from here. However, the vehicle is built locally in our plant with all imported components.

Also Read: Mercedes-Benz EQS 580 luxury EV gets over 300 bookings in India

What were the initial curve balls you faced in this electrification journey?

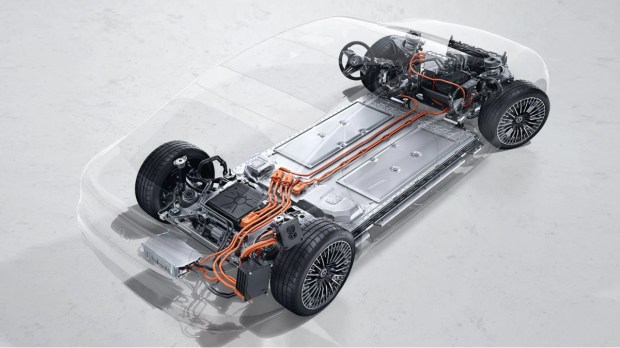

So, when we talk about challenges, it’s more of what are the steps we have taken in this electrification journey which was very, very important for us. A journey starts from the people because we feel that transformations are always driven by people. So, up-skilling people, their training and development took place with the help of having different global programmes on product processes, electrification, and battery technologies. Then there is also plant readiness where we are doing electrification in a very brownfield environment. So, greenfield is a little bit easier as compared to brownfield, but this is an altogether different story now with the brownfield and then electrification.

Flexibility is something that is our strength and that is the reason why we decided to have this approach of brownfield electrification. For this, the plant has to be ready to adapt to the various mechanical structures, a lot of electrical systems, and a lot of connected devices has to be adapted to the plant in this project.

When we talk about the logistic processes, they also have to be adapted and remapped for various things. We are speaking about battery products now. The battery also qualifies in the special hazardous material category, and it has its protocols. People need to be educated and trained to handle these processes. So we have taken a lot of steps towards the logistic processes.

Then comes a lot of testing and calibration measures. There are special rooms which are being placed in the plant. So all those steps are taken in this journey of electrification.

Where is the battery pack being manufactured?

We have a battery manufacturing facility in Germany and we are getting the complete battery pack from there. The first step towards electrification is to set up the supply chain properly. In addition to the lithium-ion pack battery cells, further supply chain processes and details are being driven from our battery manufacturing plant in Germany.

The EQS 580 is powered by a massive battery pack, but the company will have to back it up with fast chargers. So what are the plans for supporting the EV ecosystem?

I’m happy to share that Mercedes-Benz has invested in the setting of the charging infrastructure around the country, which can cover around 80% of the range as compared to our vehicle. This investment is purely done by Mercedes-Benz which is also part of the investment also done towards the fast charging equipment. There will also be some dedicated charging infrastructure for only Mercedes Benz customers. So that’s a commitment Mercedes-Benz has towards the country and our customers when we are selling green products and supporting the ecosystem by setting up charging infrastructure as well.

Mercedes-Benz had earlier stated that the company is expecting a record-breaking year in terms of sales. So does that mean in some ways the company has now managed to get over that shortage of the semiconductor chip and the supply chain issues?

So I would say yes and no. So on the one hand, the demand is increasing. On our side, as I mentioned, we have an open order of 7,000 plus units and we want to make these deliveries possible quickly.

The supply chain issue is not attributed to only one semiconductor unit, it’s a combination of various topics like limited capacities of suppliers due to COVID, then vessels shipping lines, and semiconductors on top of it. So, I would say we have not come over 100%, but the situation is getting better with the efforts from the whole team all over the world. And we are looking at improving the situation day by day. The production numbers as of date are giving good signals that it’s improving. And the demand from the customer is also improving. So we are in a good place during this festive season, which is very important for us.