Qatar will soon see a several thousand square metre school made using 3D printing technology, one of the largest building projects globally in the segment. While the project aims to demonstrate advancements in construction speed, sustainability, and precision using 3D printing, the project involves two 3D construction printers working in tandem to build the school with a combined area of 40,000 square metres, which will be located across two sites. One of the large-scale printers, the BODXL, has already been installed in Doha. While the schools are designed as two-storey buildings, this initiative is part of a larger effort to improve and modernise educational infrastructure in Qatar. The project is expected to be completed by the fourth quarter of 2026 with the total cost of the project estimated at $70 million.

Still in its early stages, 3D printing in construction is slowly picking pace in the construction industry. How does it work? It sequentially layers materials via computer-controlled processes to create three-dimensional shapes and is specifically explored for its potential benefits in terms of speed, efficiency, and customisation. The 3D printers are useful for creating new structures on-site or manufacturing components off-site for later assembly, and the printer receives dimensions from a software programme and builds the structure on a platform using materials, such as cement, plastic or liquid metals.

3D printing uses techniques like robotic arm extruders, an arm or crane-like structure that moves back and forth, releasing materials and creating layers. One can easily combine 3D printing technology with other technology such as welding to create structures like bridges that might not have a foundation. The printers use the exact amount of materials so they typically generate almost zero waste and work with little supervision to create houses or structures within a few days. This is a cost-effective way as it saves money on labour and time for projects.

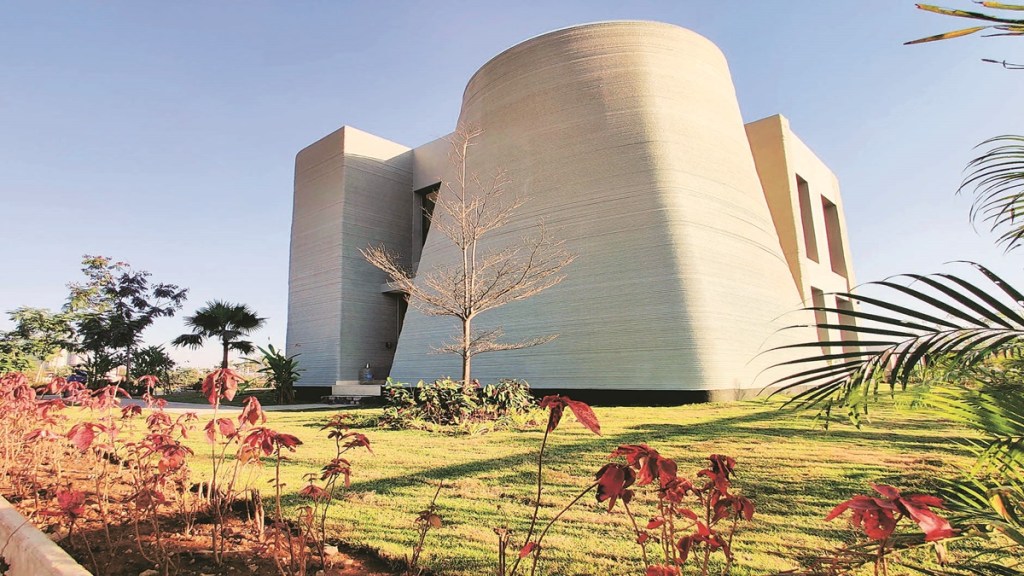

Earlier this year, MiCoB, a 3D printing company from Gujarat, unveiled a project featuring 30 3D printed cottages at Nagoa Beach, Diu. The construction is inspired from traditional ‘Bhunga Huts’ (round huts) of Gujarat’s Kutch region to blend cultural heritage with cutting-edge construction techniques. Nagoa Beach, Diu is a coastal strip so the cottages are designed to address environmental challenges like building insulation and corrosion.

A 3D-printed villa was unveiled in Pune in October last year, located at Godrej Eden Estate, Maan Hinjewadi. Bengaluru opened a 3D printed post office at Cambridge Layout in 2023 that saved cost by 30% and money when compared with conventional construction methods. A specially created robotic arm extruder was used for contour crafting and achieve the unique design in 43 days as compared to the conventional construction method of 10 months. The building was constructed by Larsen and Toubro, with technical guidance from IIT Madras, at a cost of Rs 23 lakh.

Starbucks opened a 3D printed shop in Texas, US, this year. A drive-thru and mobile order pickup, the building is a compact rectangular shape with rigid walls resembling stacked tubes, showcasing innovative concrete construction. But does this mean 3D can replace manual construction in the future? Not anytime soon. Last month, scientists at the University of Bristol, England, used the UK’s largest shaking table to mimic conditions of a medium-magnitude earthquake to assess the potential damage to a 3D-printed building. Traditional concrete design has well-established seismic behaviour, but 3D-printed concrete introduces new variables such as layered deposition, unique material properties, and non-traditional geometries. As such, assessing how these factors influence structural integrity under earthquake loading is vital.

Project leads Prof Anastasios Sextos and Dr Raffaele De Risi explained: “This experiment aims to fill the knowledge gap surrounding the dynamic response of 3D-printed units, particularly how they perform under recorded and simulated seismic events. By doing so, the team aims to identify strengths, weaknesses, and failure mechanisms specific to this construction method.”

Thus, insights from this study will help identify design parameters that optimise seismic performance, such as layer bonding strategies and reinforcement integration.

“We hope to validate whether 3D-printed concrete can meet current safety standards for seismic applications and provide a foundation for developing building codes that include additive manufacturing technologies. These findings will be essential for engineers, architects, and policymakers exploring the future of earthquake-resistant constructions,” added Risi in the report.