The semiconductor is a tiny piece of hardware but its unavailability can seriously chip away profit for corporates. This is the reason, Ajai Chowdhry, Co-Founder of HCL Technologies, often regarded as the ‘Father of Indian Hardware’ wants India to not only manufacture semiconductors but also focus on design and value-addition.

Data indicates that India imports more than $2.38 billion worth (Rs 19,627 crore) of semiconductor devices from countries like China, Singapore, Hong Kong, Japan, and the United States. Despite being the global leader in semiconductor chip design, India imports 100 per cent of its semiconductors. The Indian semiconductor market was valued at $15 billion (Rs 123,705 crore) in 2020 and is expected to reach $63 billion (Rs 519,561 crore) by 2026.

In a recent interaction with Financial Express Online, Ajai Chowdhry shared that India needs to have selective but strong FTAs (Free Trade Agreements), this will enable the companies investing in the manufacturing of semiconductors in the country to have a strong potential for export.

This was part of the 5-point strategy he charted out in the race to make the country a competitive hub and alternative destination for manufacturing. The second aspect that he stressed was to “develop a strong logistical network. This will ensure that manufacturers and the supply chain have a strong movement of goods.”

Third, according to him, it is important to have customised policies and incentives for companies coming to India, “It is not just about giving subsidies on land, water, electricity, those days are far gone. The States need to look at all what a company or the industry needs and then come up with an individualised and customised outreach plan for them.”

Fourthly, Chowdhry said the policies need to be long-term but dynamic in nature. The policymakers should have a long-term commitment to the policies but at the same time be able to revisit the policy and if necessary, tweak it every year keeping in mind the ever-evolving global scenario.

Lastly, the focus should be on designing and value-addition, not just manufacturing alone. This he said will enable the creation of technical capabilities and Ips, all the while also bringing global technologies and cost down in the country.

“I think in the coming years India needs to be strongly prepared for geopolitical situations. I believe we have to be very strong in the next 20 years and have a plan ready for the same. The coming decades belong to India, if we are prepared for it,” Chowdhry added.

The global chip dynamics

The global semiconductor market is pegged to be around $574.1 billion (Rs 4,733,778 crore) in 2022.

Interestingly according to the Semiconductor Industry Association (SIA)/Boston Consulting Group (BCG) study, there are more than 50 points across the semiconductor value chain where one region holds more than 65% of the global market share and that is Taiwan.

These are potential single points of failure that could be disrupted by natural disasters, infrastructure shutdowns, or international conflicts, and may cause severe interruptions in the supply of essential chips. About 75% of global semiconductor manufacturing capacity, for example, is concentrated in China and East Asia. In addition, 100% of the world’s most advanced (below 10 nanometers) semiconductor manufacturing capacity is currently located in Taiwan (92%) and South Korea (8%).

Taiwan, which has been a powerhouse for the supply of semiconductors has been grappling with its own set of challenges. Starting with the global pandemic to the geopolitical situation, countries globally are looking to de-risk themselves and find alternatives to meet their requirements. India finds itself in a very promising position, and if it were to take advantage of this, it would very well mean a once-in-a-lifetime opportunity.

Early days for start-ups

Chowdhry is currently the Chairman of Epic Foundation India, a not-for-profit that aims to revive the electronics industry in the country by creating Indian products and brands for electronics products of national importance.

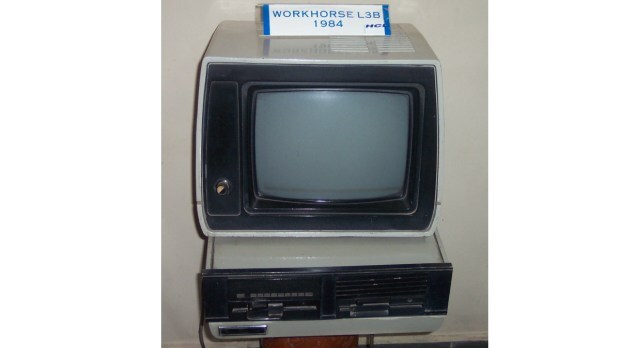

Reminiscing the early days at HCL, he said “It was very tough when we started, there were hardly any resources available and getting access to finance was a big challenge. The biggest problem that we faced when we started was that HCL Technologies wanted to design and manufacture computers. There were hardly 100 computers in the whole of India at that point of time, microprocessors had just started appearing. Then there was the requirement of having a license and manufacture in India.”

These challenges do not exist anymore, and hence, the current generation of entrepreneurs has a better environment to take advantage of India’s talent and manufacturing ecosystem. “Today you have angel investors, VCs, mentors, start-up India program, among others. While the money for start-ups has reduced in the last few years but that’s a right thing that has happened, that has straightened them out,”

Chowdhry explained highlighting the changing scenario and how it is helping make startups more responsible.

Localisation versus globalisation

Over the years, the global supply chain has led to different functions of the manufacturing and service industry being concentrated in various geographies. In Asia, China’s focus on manufacturing and India’s on software services made the two neighbours a leading partner of choice for various multinationals.

But in the last two years, post-pandemic, increasing geopolitical differences and over-reliance on imports have forced many countries to revisit their policies to encourage local manufacturing. “When China adopted zero Covid policy that shook the global supply chain and companies who were solely dependent on that country, their revenues fell by 30-40 percent. And thus there was a big movement of looking at alternative manufacturing to China. Electronics is a global supply chain and surely one cannot do everything on one’s own. What we need to understand is that the time has now come for a large country like India to change completely, just in a way America is. The reason is that there is a very large domestic market and requirements. In that way China, India, and the USA are similar,” shared Chowdhry.