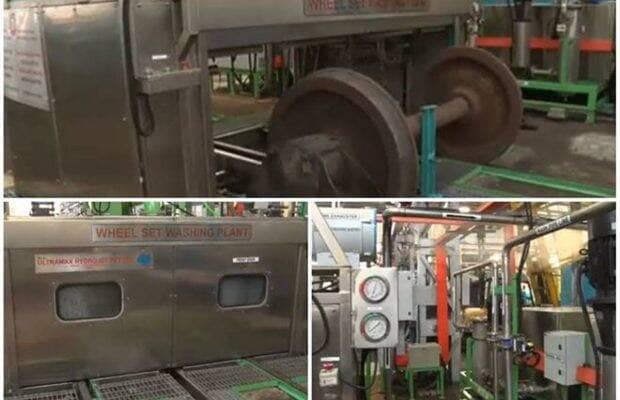

Wheel Set Washing Plant: In a bid to ensure safe train travel, Indian Railways is cleaning wheels with hi-tech technology like never before. To offer a complete solution for cleaner wheel sets, saving time and water, Wheel Set Washing Plant (WSWP) has been commissioned with the latest technology at Carriage Workshop, Lallaguda, under the South Central Railway zone. According to the national transporter, as per the safety guidelines, there should be no man movement inside the machine while conveyor movement and door open/close, while the siren is in alarm. Also, before the cycle starts, it should be ensured that there is no person inside the washing booth. Watch the video, shared by the Railway Ministry, to know how the Wheel Set Washing Plant works:

Clean wheels ensure safe travel :

Wheel Set Washing Plant (WSWP) commissioned with latest technology at Carriage Workshop, Lallaguda in South Central Railway offer complete solution for a cleaner wheel sets, saving time and water. pic.twitter.com/kodTIdNbtF

— Ministry of Railways (@RailMinIndia) December 10, 2021

Take a look at the procedure below to know how Indian Railways starts the Wheel Set Washing Plant:

1) Switch ON the control panel and ensure the 3 phase power supply is ok

2) Clean the entire plant before starting and end of every shift

3) Ensure all the tank filters, online filters are in cleaned condition before starting the Wheel Set Washing Plant

4) Ensure all the filters are in place in the proper location

5) Ensure the PH value is greater than 12 in washing and rinsing if required top up with relevant solutions

6) Make sure all the tank level is within the limit

7) Switch ON the heater of all tanks

8) Ensure all the tank temperature is in the range as per set temperature

9) Sludge removed from oil skimmer before starting and ending of every shift

10) Ensure the compressed air pressure is 5-6 bar & above and maintain the oil level in FRL

11) Ensure the wheel movement area is not obstructed

12) Load and lock the wheel set before starting the cycle