UK-based technology start-up Helixx has selected Siemens Xcelerator portfolio of industry software and services to assist the design, development, validation, delivery, and management of its innovative electric vehicle manufacturing system.

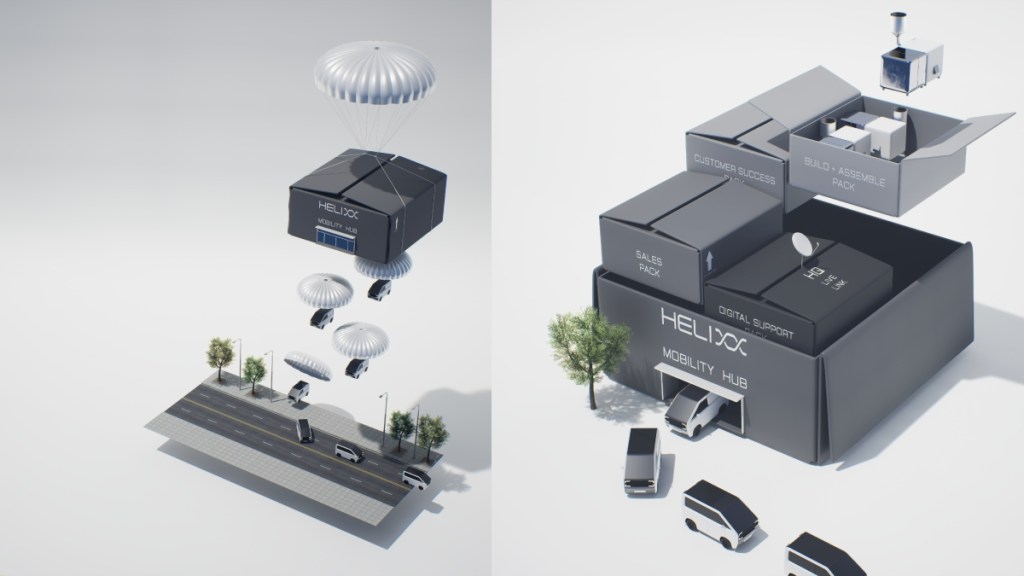

The start-up claims that the Helixx manufacturing system, a unique global solution will empower customers to operate licensed factories, known as Helixx Mobility Hubs, producing a range of mini commercial electric vehicles (EVs) virtually anywhere in the world. The Helixx vehicle range will comprise of Cargo commercial delivery van, Truck pick-up for construction sites, and open-body Tuk and closed-body Ride for ride-hailing.

It may be recollected that in March 2023, Financial Express Online exclusively revealed the start-up’s plans for India and how it planned to disrupt the commercial electric vehicle market.

The company will be responsible for engineering the vehicles and the manufacturing system by which they are produced. While Helixx will manufacture the first vehicles at its concept hub in Oxfordshire and in further pilot hubs in the UK and Singapore producing 10,000 Helixx vehicles a year by 2025 the brand’s mission and ambition go far beyond that.

Steve Pegg, CEO and Co-Founder, Helixx said: “Helixx has created the world’s first commercially viable system for a factory of the future. But Helixx is not manufacturing a product; it’s a process that can be handed over via a licence to customers anywhere in the world. It enables Helixx partners not just to make a much-needed zero-emission commercial vehicle, but to also run the entire manufacturing system and supply chain autonomously with minimal complexity.”

“Collaborating with Siemens and having access to the industry-leading Siemens Xcelerator software portfolio for digital transformation is pivotal to Helixx’s strategy and is a key part of unlocking global growth and supporting our licence holders. Our collaboration with Siemens enables Helixx to develop quickly and amplify efficiency, transparency and quality continuously at every stage of the value chain – from initial factory feasibility study to vehicle end-of-life recycling,” he added.

The Siemens Xcelerator portfolio supports automotive and aerospace OEMs across the globe, and its technology can be seen across major industries from food, energy, transport and marine.

A key advantage of Siemens Xcelerator is the system’s ability to offer a ‘Digital Twin’ for every single element of the Helixx manufacturing ecosystem. Many businesses use digital twins for individual or one-time applications. Creating a digital twin of everything, which entails creating a digital representation of each physical process, component, facility, and environment, will give Helixx a unique advantage through the ability to design, realise and optimise, right from first principles.

Every stage of the process, from each initial customer factory site survey, equipment installation, operator training, supply chain management and manufacturing to retail, productivity, service and maintenance and vehicle end-of-life recycling can be modelled via Siemens’ digital twin technologies and validated ‘in the cloud’ prior to realisation. Once each customer factory, or Helixx Mobility Hub is operational, it will be fully integrated into the Helixx ecosystem and digitally monitored and managed in real-time at Helixx Mission Control in the UK.

Teruyoshi Adachi, CTO, Helixx said: “Leveraging the Siemens Xcelerator technologies will enable Helixx to weave digital threads through the entire fabric of our business model. Development cost and complexity of not only our mini commercial EVs but the entire end-to-end operational chain has already been reduced by 20 percent. This simplification unlocks the crucial commercial viability for small, affordable EV manufacturing for our licence holders.”

“The technology, which encompasses elements including simulation, collaboration, software systems engineering, accelerated product development, manufacturing, operations, and IoT analytics, effectively enables us to ‘see the future,’ at every stage and on every level of detail from micro to macro. From determining the resources required to build a specific number of vehicles and optimising operator ergonomics to validating the efficiency of processes and the longevity of components, the Siemens Xcelerator portfolio provides a complete and continuous holistic digital overview,” he added.

Ben Sheath, VP and MD, UK & Ireland Siemens: “The approach being taken by the team at Helixx is an innovative take on building a transportation industry segment from the ground up. Not only do Helixx customers not need to research and develop a physical product, but they are also free from the cost and complexity of developing the associated manufacturing system. Instead, everything is provided for them through the Helixx ecosystem. A modular product from a modular factory is, perhaps, the production architecture needed to realise the factory of the future. We are delighted that Helixx has selected our toolset and chosen to deploy our end-to-end digital twin technologies to help them deliver its ground-breaking vision and production model to reality and we look forward to playing a part in helping it bring in zero-emission mobility and supporting sustainable economic development in emerging markets.”