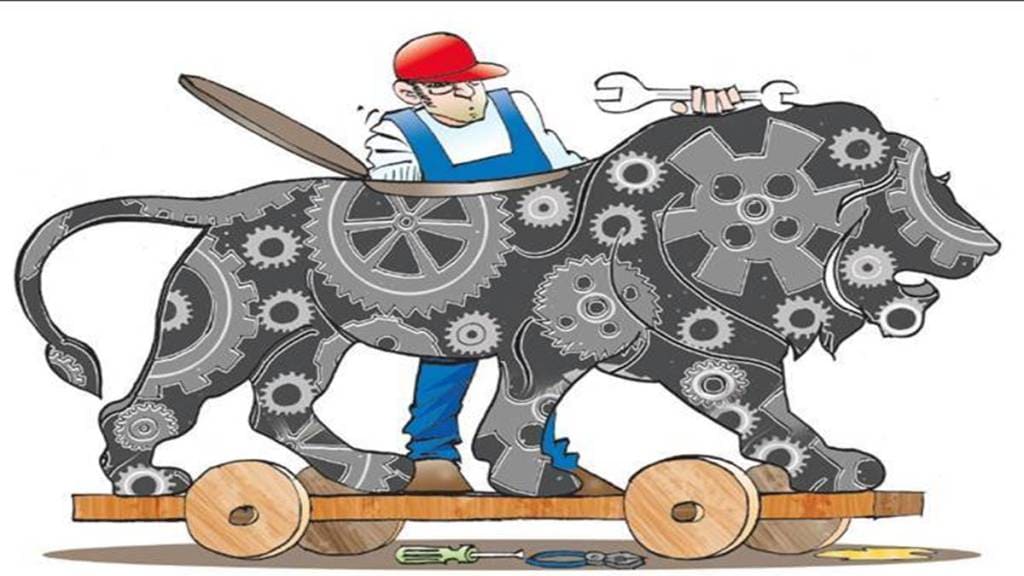

India’s defence sector has been undergoing a significant transformation over the past few years, driven by an increasing emphasis on boosting domestic manufacturing capabilities. The government’s ‘Make in India’ initiative has played a pivotal role in this transformation, aiming to reduce dependence on foreign suppliers and enhance self-reliance in defence production. This shift is not only crucial for national security but also for economic growth and technological advancement. The allocation of budgetary resources to support indigenous defence projects underscores the government’s commitment to this strategic goal. However, several challenges remain in realizing the full potential of domestic defence manufacturing.

Boosting Domestic Defence Manufacturing: The ‘Make in India’ Initiative

Launched in 2014, the ‘Make in India’ initiative aims to transform India into a global manufacturing hub. In the defence sector, this initiative has been particularly impactful, with several key policies and reforms introduced to promote domestic production. The government has relaxed foreign direct investment (FDI) norms, allowing up to 74% FDI under the automatic route and 100% through government approval in the defence sector. This has encouraged several international defence companies to set up joint ventures and manufacturing units in India.

Additionally, the government has launched various schemes and policies to support indigenous defence manufacturing. The Defence Production and Export Promotion Policy (DPEPP) 2020 outlines a roadmap to achieve a turnover of Rs 1,75,000 crore (US$25 billion) in defence manufacturing by 2025, including an export target of Rs 35,000 crore (US$5 billion). The policy emphasizes the need for self-reliance and aims to reduce imports through the development of indigenous capabilities.

Budget Allocations and Support for Indigenous Defence Projects

The Union Budget has increasingly reflected the government’s commitment to enhancing domestic defence manufacturing. In the 2023-24 budget, the defence sector received an allocation of Rs 5.94 lakh crore (US$79 billion), marking a significant increase from previous years. A substantial portion of this budget is directed towards capital expenditure, which includes the procurement of new equipment and modernization of existing assets. Notably, 68% of the capital procurement budget is earmarked for domestic industries, underscoring the government’s focus on supporting local manufacturers.

Several major defence projects have benefited from these budgetary allocations. For instance, the development of the Light Combat Aircraft (LCA) Tejas, the Advanced Medium Combat Aircraft (AMCA), and the Arjun Main Battle Tank are significant milestones in India’s journey towards self-reliance. The budget also supports the production of indigenous missile systems, such as the BrahMos supersonic cruise missile and the Akash surface-to-air missile system.

Furthermore, the government has established defence industrial corridors in Uttar Pradesh and Tamil Nadu to create a robust ecosystem for defence manufacturing. These corridors aim to attract investment, enhance connectivity, and foster innovation through collaboration between industry and academia.

Challenges in Domestic Defence Manufacturing

Despite these efforts and the increased budgetary support, several challenges hinder the growth of domestic defence manufacturing in India. One of the primary challenges is the lack of advanced technology and expertise. While the government has made efforts to attract foreign investment and technology transfer, there is still a significant gap in critical technologies needed for advanced defence systems.

The defence manufacturing sector also faces challenges related to infrastructure and supply chain inefficiencies. The defence industrial base in India is still developing, and there are gaps in the supply chain that can lead to delays and increased costs. Building a robust supply chain that can support the manufacturing of complex defence systems requires significant investment and time.

Moreover, the defence procurement process in India has historically been plagued by bureaucratic red tape and delays. Although reforms have been introduced to streamline the process, further efforts are needed to ensure timely procurement and project execution. Simplifying the procurement process and reducing bureaucratic hurdles can significantly enhance the efficiency and effectiveness of defence manufacturing projects.

Human resources and skill development also pose a challenge. The defence sector requires a highly skilled workforce with expertise in various domains, including engineering, research and development, and project management. There is a need for focused initiatives to develop a talent pool that can meet the demands of the defence manufacturing sector.

The Way Forward

To overcome these challenges and fully realize the potential of domestic defence manufacturing, a multi-faceted approach is needed. Continued investment in research and development (R&D) is crucial to bridge the technology gap. Collaborations with foreign partners can facilitate technology transfer and help build indigenous capabilities.

Strengthening the defence industrial base through infrastructure development and supply chain integration is essential. The government should continue to incentivize private sector participation and foster public-private partnerships to leverage the strengths of both sectors. Initiatives such as the defence industrial corridors should be expanded and further developed to create a conducive environment for defence manufacturing.

Simplifying the procurement process and reducing bureaucratic hurdles can enhance the efficiency of defence projects. The government should focus on creating a transparent and streamlined procurement framework that ensures timely execution of projects.

Investing in human resources and skill development is vital for the long-term success of domestic defence manufacturing. Educational institutions and training centers should collaborate with the defence industry to develop specialized programs that cater to the needs of the sector.