Rat-Hole Mining Impacts: After repeated hindrances, the Uttarkashi rescuers decided to rope in rat-hole miners to bring out the 41 workers, who have been trapped for more than 2 weeks. The experts have finally opted for a more successful-yet-hazardous option – rat-hole mining.

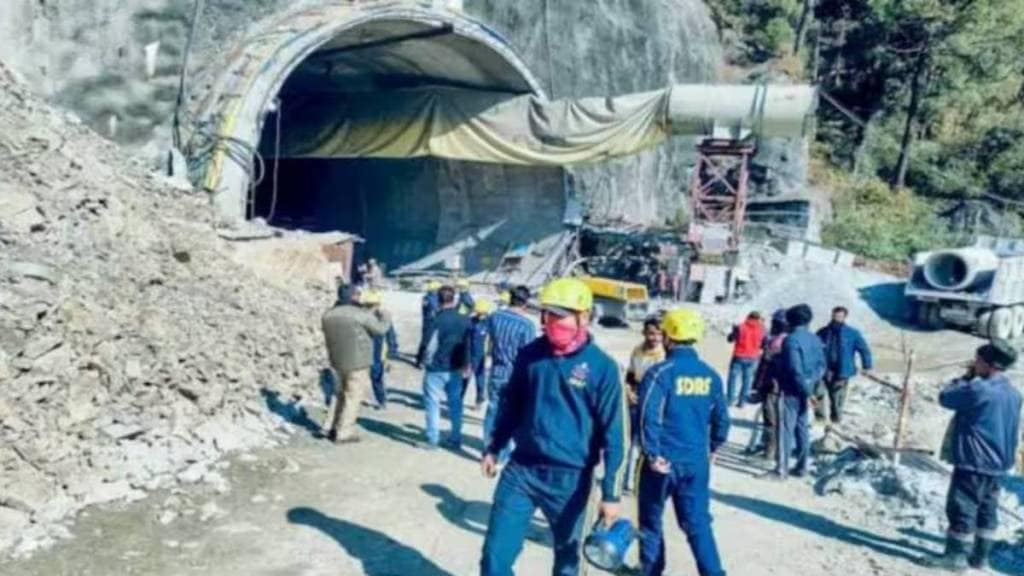

Rescuers at the Silkyara tunnel have made progress, reaching the 50-meter mark in their efforts to save 41 workers trapped for 16 days. They now face a challenge of digging through 10 meters of rubble using the rat-hole mining technique.

Rat-hole mining is a risky method where small groups of miners go down narrow tunnels to extract small amounts of coal. In Meghalaya, this practice involved digging narrow pits, descending with bamboo ladders and ropes, and manually extracting coal with tools like pickaxes. However, due to safety concerns and unregulated mines, the National Green Tribunal banned rat-hole mining in Meghalaya in 2014.

The current rescue team, comprising 12 rat-hole mining experts, is using this technique to excavate the collapsed portion of the tunnel. The workers are manually removing debris, and an 800-mm diameter pipe is being inserted by an auger machine through the rubble.

Neeraj Khairwal, the Uttarakhand government’s nodal officer, clarified that the rescued individuals are not rat-hole miners but experts in the technique. They will be organized into teams of two or three, working in the steel chute laid into the escape passage.

Rajput Rai, a rat-hole drilling expert, explained the process as one person drills, another collects rubble by hand, and the third places it on a trolley for removal. The shift to rat-hole mining occurred when a large auger machine got stuck at 47 meters.

The National Green Tribunal had previously banned rat-hole mining due to safety hazards and incidents like flooding during the rainy season. The current rescue team aims to use the expertise of these individuals to safely navigate the challenging conditions and bring the trapped workers to safety.