Cummins Group in India (Cummins), a leading power solutions technology provider is showcasing what it claims is an industry-first, next-generation fuel-agnostic platform, along with the innovative Single Module Aftertreatment system at the Symposium on International Automotive Technology (SIAT) 2024 in Pune.

As part of its Destination Zero strategy, Cummins aims to go further and faster in minimising the greenhouse gas (GHG) and air quality impacts of its products. The company is pursuing a dual-path approach – acting today to reduce emissions from internal combustion engines (ICE) while simultaneously investing in the development of new, zero-emissions products, to help customers navigate through the energy transition.

Anjali Pandey, COO, Cummins Group in India said, “As an industry leader, Cummins recognises its crucial role in addressing global climate challenges. We understand that transitioning to a decarbonised future is not a light-switch event and will require multiple solutions. Hence, we are continuously investing and innovating to develop technologies that align with our commitment, ensuring our customers’ success today while contributing to a more sustainable tomorrow. Our showcase at SIAT 2024, reflects our versatility and adaptability to meet the evolving needs of the transportation sector.”

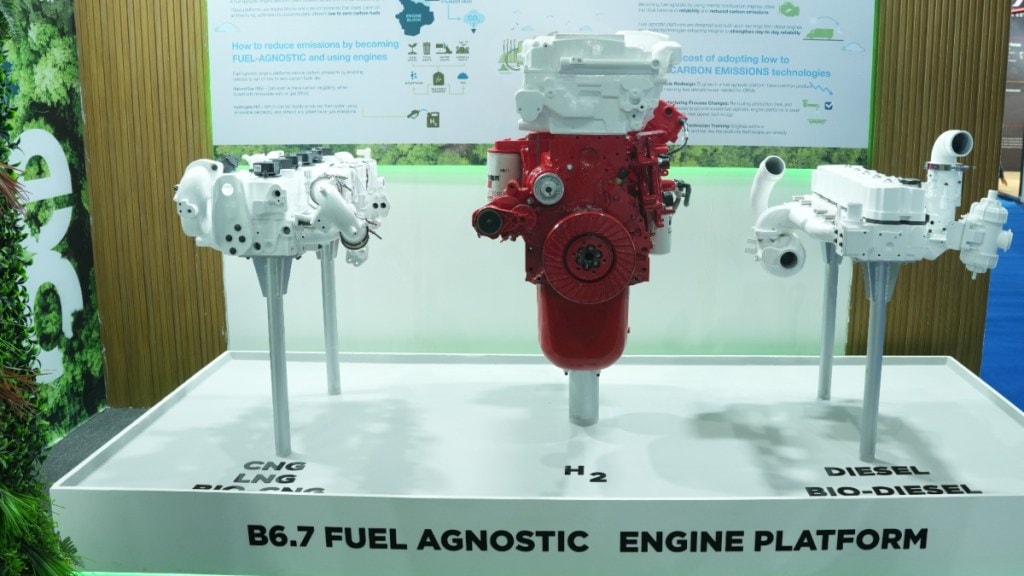

Fuel-agnostic platform

Cummins states that in the pursuit of decarbonisation, it is imperative to bring various powertrain technologies that leverage the available low and zero-carbon fuels. This approach provides end users with options and flexibility to select fuels based on infrastructure availability thus optimising the economics of transportation operations.

The fuel-agnostic architecture of this platform utilises a common base engine, with the application of innovative technologies like a Direct Injection Fuel System, two-stage turbocharging, overhead cam, closed crankcase ventilation, and pent-roof cylinder head design.

Additionally, it features Cyber Security and Functional Safety Compliant Control Modules tuned for specific fuels such as diesel, natural gas, renewable natural gas, and hydrogen. This platform ensures diesel-like performance across fuels, enabling OEMs to offer multiple fuel types with minimal product modification, and expediting market entry at the most optimum cost.

At the SIAT 2024, Cummins’ fuel-agnostic platform concept will be demonstrated through:

Hydrogen Internal Combustion Engine

The Cummins Hydrogen Internal Combustion Engine represents a significant stride towards sustainable and cleaner energy solutions in the automotive and industrial sectors. Leveraging the power of hydrogen as a clean fuel source, the internal combustion engine operates with lower emissions. Combined with green hydrogen, it produces zero CO2 emissions from well-to-wheel. During the event, Cummins will showcase solutions specifically designed for medium- and heavy-duty trucks and buses. These solutions highlight the engine’s ability to support decarbonisation across a wide range of duty cycles.

Natural Gas Engine

Natural gas engines present a reliable and effective solution for reducing emissions while maintaining strong performance. With well-established credibility as an alternative power technology, these engines align with India’s vision of increasing the share of natural gas in the energy mix from 6% to 15% by 2030. To achieve this vision, substantial investments are planned for the development of Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG) infrastructure. These investments will further enable the adoption of natural gas engines supporting the government’s long-term objectives.

Latest generation diesel

The latest-generation advanced diesel platform, which has a strong foundation of nearly 700,000 Euro VI, low-emission engines will be exhibited. These advanced diesel engines, further optimise fuel efficiency, enabling customers to achieve lower GHG emissions while enhancing power and torque.

Single Module Aftertreatment System

Cummins is also showcasing its ultra-high efficiency aftertreatment system 9-inch (0.229 Meters) Single Module. This system is up to 70% smaller and 40% lighter compared to systems with similar architectures. It offers improved NOx conversion efficiency that removes over 99% of all particulate matter (PM) by weight and count. The product is optimised with a liquid-only, freeze-robust UL2.2 dosing system, which significantly improves reliability. ‘Made in India’ with over 70% localised components, this product readily adapts to a variety of applications as it is available in catalyst diameters ranging from 5.66 inches (0.144 meters) to 13 inches (0.330 meters).