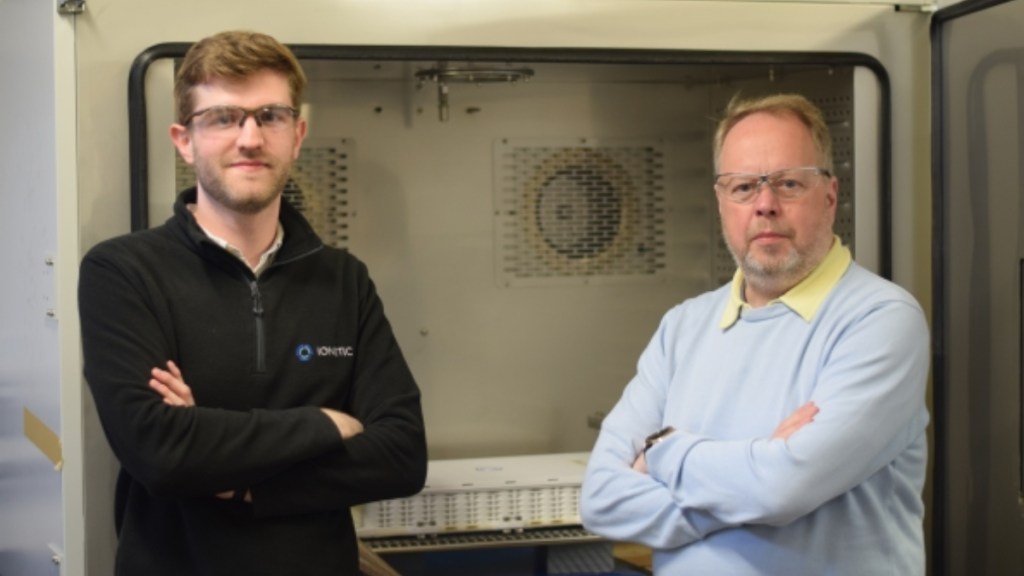

Ionetic, a UK-based start-up focussing on electric vehicle battery pack technology has appointed automotive industry veteran Dr. Andy Palmer, as its Chairman.

The start-up says Dr. Palmer joins at a key stage in its development, as the business continues to focus on onboarding clients and planning the opening of its first giga-scale manufacturing facility in the UK.

He will draw from his wealth of knowledge and experience to support strategic growth and sales as the business progresses towards ultimately achieving multi-GWh battery pack production capacity.

Dr. Palmer has over 44 years of experience in the industry and is often referred to as the ‘Godfather’ of EVs.

He has held several leadership positions including as COO and Chief Planning Officer Nissan Motor Corporation; President & Group CEO, Aston Martin Lagonda; Chairman, Optare Board; Executive Vice-Chairman and CEO, Switch Mobility.

Dr. Palmer oversaw the development and introduction of the world’s first mass-market EVs, the Nissan LEAF and Nissan e-NV200, before leading the launch of 4 core models and 9 derivative vehicles at Aston Martin Lagonda.

“I have witnessed first-hand the need for more cost-effective battery pack solutions that can still meet the performance criteria of automotive OEMs, especially in lower volume. Ionetic is doing just this, and I have great belief that its offering will significantly reduce the challenge and headaches of electrification for OEMs,” said Dr Palmer.

James Eaton, CEO and Co-Founder, Ionetic said: “Ionetic was founded to support vehicle manufacturers in making the shift to electrification, bringing innovation to the industry to make that transition easier and faster. Andy has demonstrated that same commitment to intelligent innovation throughout his career.”

Ionetic leverages a unique design platform and end-to-end vertical integration to cut development cost and time for automotive manufacturers bringing new EVs to market. It claims its EV battery pack design platform can produce a bespoke battery pack design in minutes, delivering a solution that efficiently blends cost optimisation with high levels of customisation and performance. As a result, Ionetic says it can produce battery packs that offer over 30 percent more energy density than off-the-shelf solutions, while reducing development costs by over 90 percent.

The start-up claims once its first UK-based factory is operational, it will be the only UK-based EV battery pack developer to offer an end-to-end solution – managing the entire process from initial design conception, through to homologation, testing and giga-scale production.