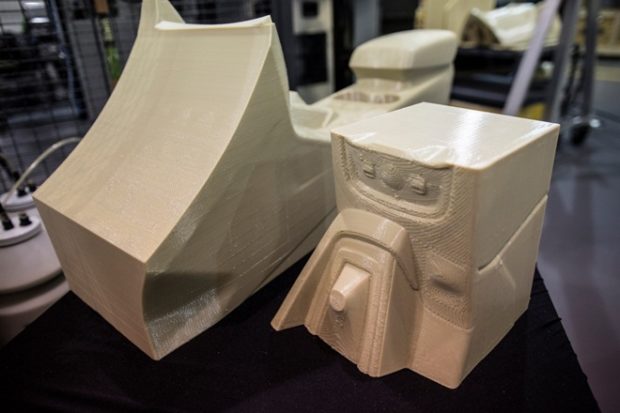

Ford Motor Company has become the first automotive company to test 3D printing of large-scale car parts using the Stratasys Infinite Build 3D Printer. The aim of the test is to ascertain the potential applications of low-volume future production vehicles such as Ford Performance vehicles or for personalised car parts. The Stratasys printer can print car parts of any shape and size, thereby translating into a more efficient and economical way to produce low-volume car parts and tooling and prototype parts as well. The new 3D print system is presently located at Ford’s Research and Innovation Center in Dearborn, Michigan, US.

3D printing has been gaining popularity among carmakers and suppliers in the recent few years due to multiple benefits, cost being one of them. This technology also allows for manufacturing of lighter parts, which plays a crucial role in increasing the fuel-efficiency and lowering emissions. A 3D made a spoiler, for example, may weigh less than half of its metal-cast equivalent. As a result, this technology also makes sense for motorsport racing.

Using 3D printing, companies can also manufacture customised parts for customers who intend to personalise their vehicles. Owing to the growing usage of the technology, Global Industry Analysts reported that by 2020, the global market for 3D printing is expected to reach $ 9 billion.

How the technology works?

Specifications for the part are transferred from the computer-aided design program to the printer’s computer, which analyses the design. Then, the device goes to work, printing one layer of material at a time, in this case, plastic – and then gradually stacking the layers into a finished 3D object.

Also Read: While Ford improves, General Motors fails in NCAP crash testing

When the system detects that the raw material or supply material canister is empty, a robotic arm automatically replaces it with a full canister. This allows the printer to operate for hours or days while unattended.