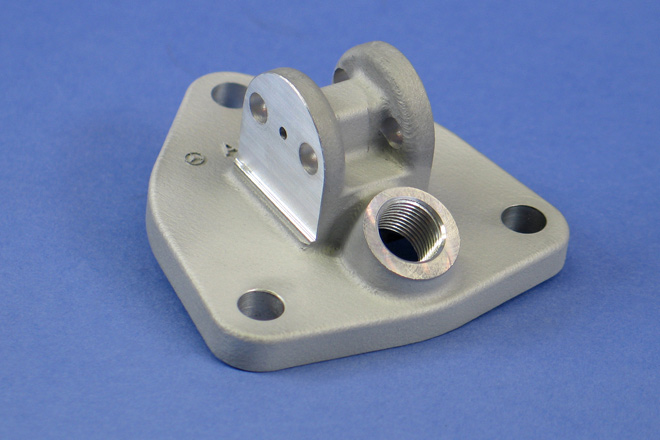

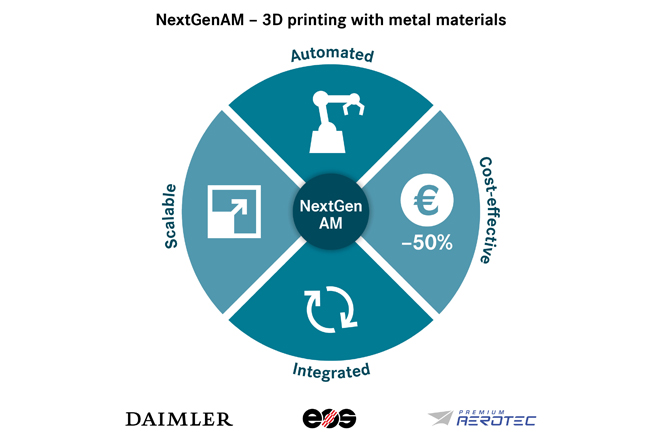

The joint project called ‘NextGenAM’ between Daimler, Premium AEROTEC and EOS has proved to be a success that shows significant potential. The three companies jointly attempted an automated metallic 3D printing pilot project which they claim has been successful. The project shows huge potential for the production of replacement part and series production components.

Currently, the manufacturer has begun producing of truck parts using the technology which is called ‘Additive Manufacturing’ the process involves the application of layer after layer of thin material, which is then hardened by an energy source. Along with plastics and ceramics, it is also possible to produce metal components in a 3D printing process. Further expansion of manufacturing of components for conventional and electric cars are currently being asses by the company. The German multinational automotive corporation has stated that this automated construction method of components can reduce manufacturing costs by up to 50% compared with existing 3D printing systems. The fully automated production process and continuous data string, managed from a control station. The system can also be feature integration; scalable process chain that covers all steps from data preparation to quality assurance as well.

Jasmin Eichler, Head of Future Technologies at Daimler AG. “3D printing also makes particular sense during the advance development of vehicles. The low numbers required can often be produced more cost-effectively, and faster, with Additive Manufacturing than with conventional production processes.”

Dr Thomas Ehm, Chairman of the Executive Board of Premium AEROTEC said; “The successful conclusion of NextGenAM thus represents another important building block in our strategy.”

The aim of the ‘NextGenAM’ project was to develop a digitalised next-generation manufacturing line which would be able to produce aluminium components for the automotive and aerospace sectors and deliver them at a significantly reduced cost when compared to what is current technology offers.