INDUSTRY PARTNERS

Overview

From big data to cloud computing, the benefits of modern technologies are helping manufacturers enhance their speed of operations, streamline the manufacturing process, reduce human intervention and minimise errors in the process. Besides, technologies such as artificial intelligence, machine learning and additive manufacturing are helping them ensure efficiency, reduce waste and increase plant productivity and overall profitability.

To achieve this goal, Indian manufacturers will have to speed up their plans for factory automation and rebuild human resources to drive growth. Financial Express' Future Factory 4.0 is a step in that direction. The event will unfold the value of Industry 4.0 through next generation smart technologies in harnessing the benefits of AI, Robotics, IoT, Digital Twin, Additive Manufacturing and other futuristic technologies.

The inaugural edition of Future Factory 4.0 will bring together business leaders in manufacturing, policymakers, industry experts and veterans under one roof to brainstorm and create an independent ecosystem in making India the "factory to the world". The event would connect key stakeholders across the entire spectrum of manufacturing including automotive, defence, electronics, MSME and provide a platform to shape the Indian manufacturing agenda in 2023 and beyond.

ABOUT THE EVENT

The FE Future Factory: Spotlight Additive Manufacturing & Digital Twins enables manufacturers and researchers to get inspired and educated about emerging AM & DT technologies that upskill the workforce, improve quality and advance the future of manufacturing.

The half day conference-cum-exhibition will be an experience rather than merely an event. A world of interactive learning and technological demos will be presented to participants. Live presentations, various points of connection, and inspirational keynotes will impart unmatched understanding and expertise.

All manufacturers should take advantage of this fantastic chance to learn about the newest disruptive technologies in manufacturing and network with industry peers.

TOPICS OF DISCUSSION

ADDITIVE MANUFACTURING

- Embracing & navigating Complexity of Design

- Innovations and future technologies in additive manufacturing

- AM at The Point of Care (Healthcare, Lifesciences & medicine)

- The Value of Additive Manufacturing in the Automotive Industry

- Emerging Alloys and Metallic Materials for AM

- Artificial intelligence enabled AM system using 5G and industrial IoT

- AM with a focus on Sustainability and environment

- Challenges to overcome in the AM technology

DIGITAL TWIN

- Realising tech-enabled future work environments

- The art of decision-making using digital twin

- Designing the digital twin processes and information requirements in the product life cycle

- Leveraging digital twin technology to enhance supply chain productivity

- Driving business value from digital twin

- Evolved digital twin, extended benefits

FOCUS INDUSTRIES

Automotive & Transportation

Home, Lifestyle & Hi-tech

Electronics & Semiconductors

Aviation, Aerospace & Defence

Infrastructure, Energy & Materials

Industrial Machinery & Heavy Equipments

Healthcare, Life-Sciences & Medicines

Consumer Products & Retail

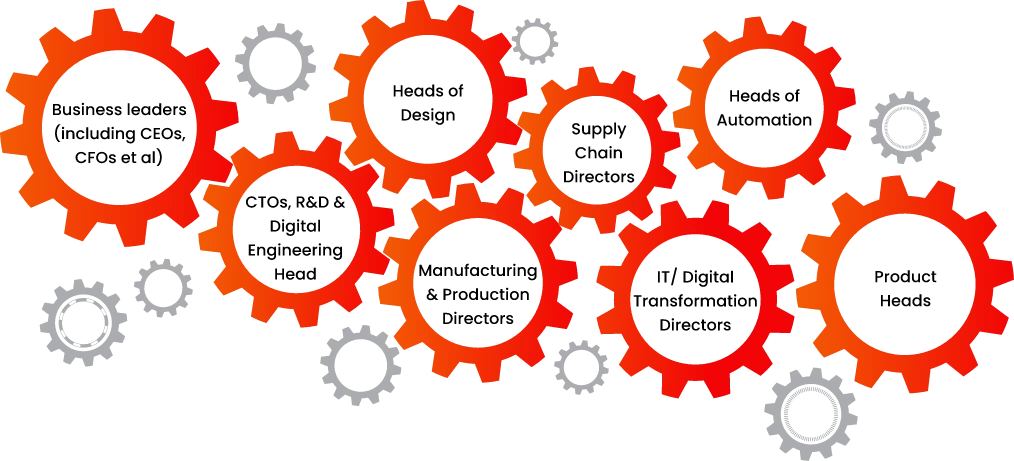

Who ShouldAttend

This conference is not just another gathering of experts to discuss digital twins; rather, it is a senior-level platform for business decision-makers who want to research and assess cutting-edge innovations in technology and business strategy. Over 150 attendees will join this Congress including.

WhyAttend

Contact Us

For Partnership Opportunity

For Speaking Opportunity

Riya Chopra

For Delegation

For any urgent matters or issues requiring immediate escalation, please write to rohit.singh@financialexpress.com

24th March 2023

24th March 2023